Shaft Runout Monitoring

Custom designed here at Specialist Tooling Technologies Ltd

What our software can achieve

Live recording of shaft runout.

Using Bluetooth measuring devices this software was created to record measurement data of power generation turbine shafts during slow rotation and produce detailed reports of the results.

There are two types of shaft, each having several inspection procedures at several different stages. Measurements are recorded when the shaft arrives, after machining and during testing.

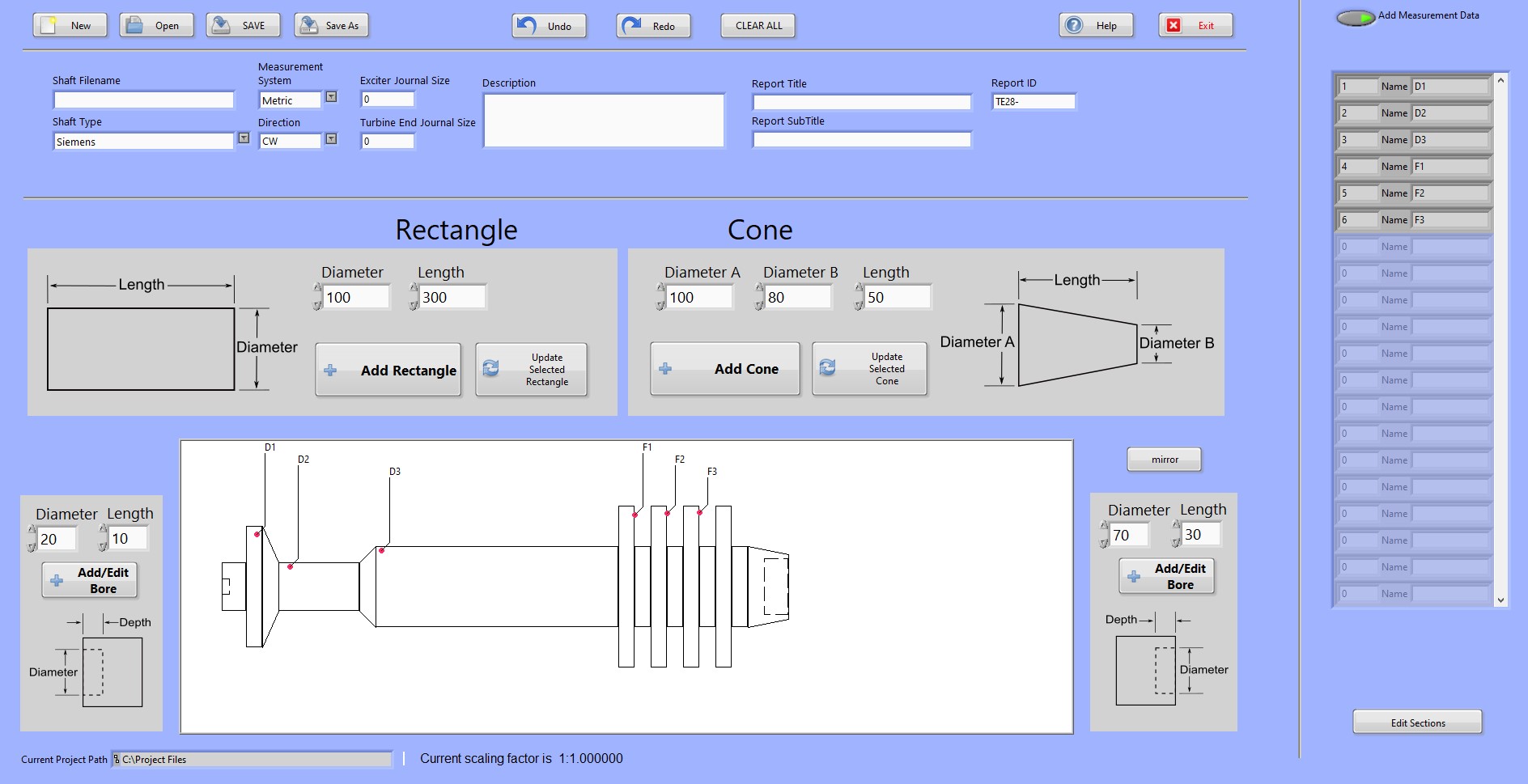

A project begins by loading a shaft file. The shaft files are designed in a companion application and is used to create a representation of the shaft and define the areas to be measured. The measurements required are labelled and shown on the diagram. The shaft is then saved as one type or the other.

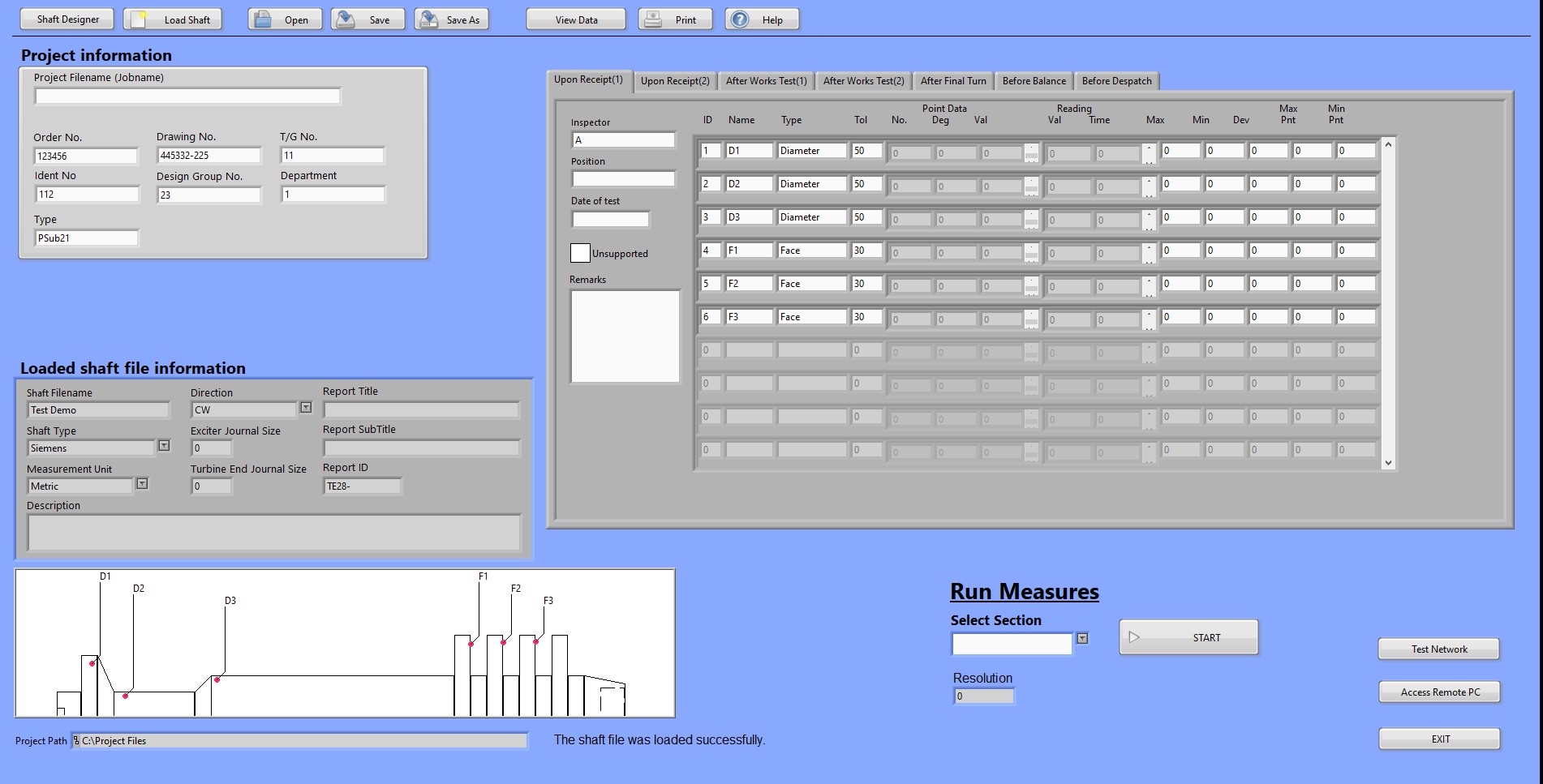

To begin a project the shaft file created in the shaft designer is loaded into the main application. The shaft type defines the inspection requirements and the report types available.

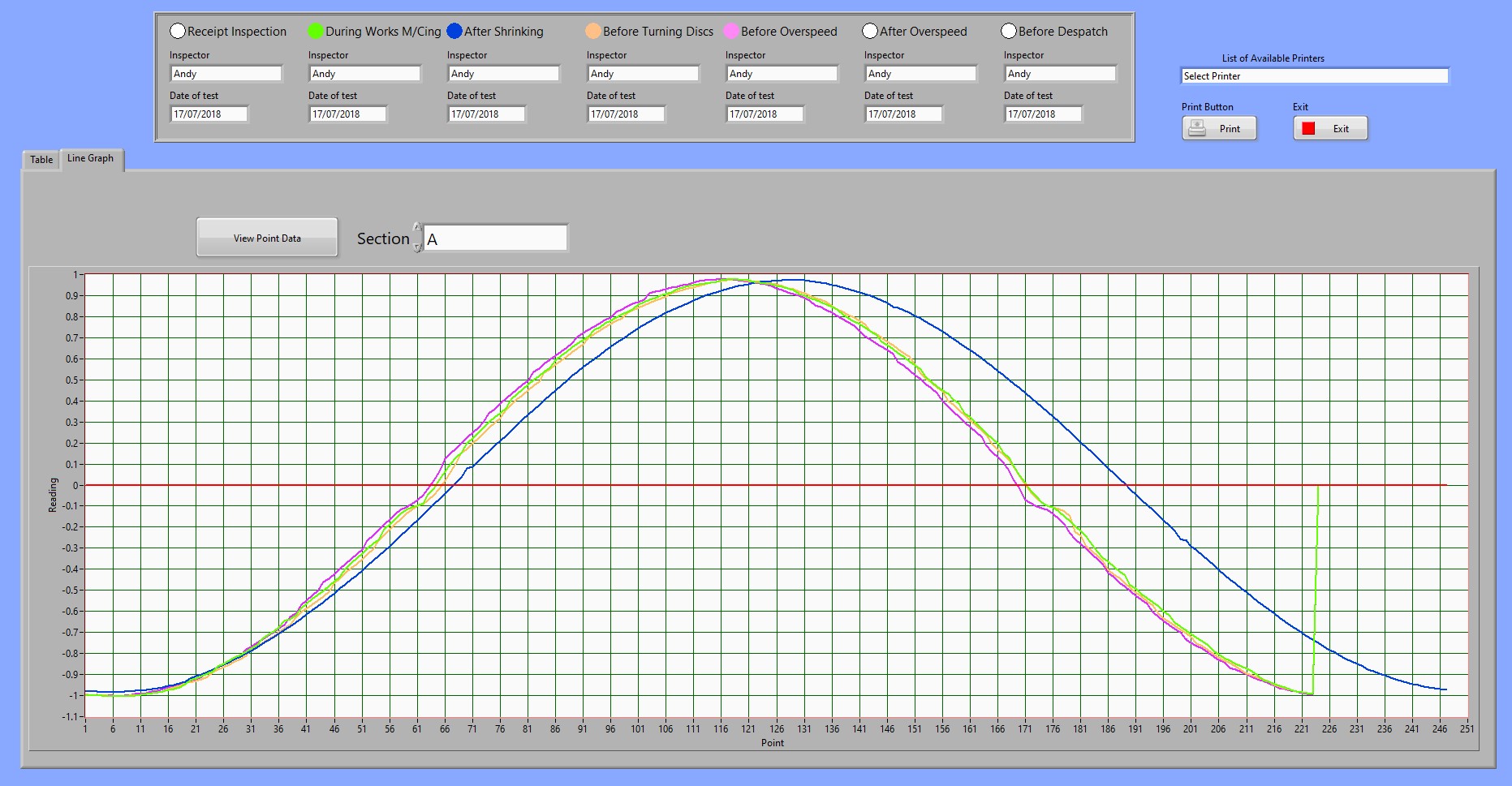

Once the inspector enters some details the measure section can be selected and data collection can begin. The process is then automatic and the results are returned to the main application.

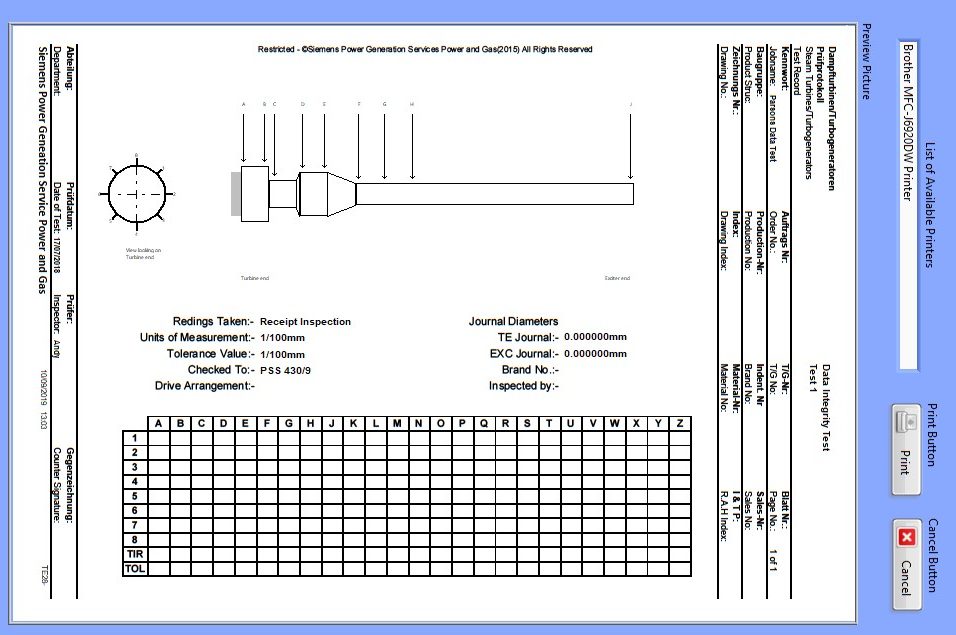

Reports are generated and previewed before printing. Reports can be saved by printing to PDF.