Control Panel Building

Services here at Specialist Tooling Technologies Ltd

How to design a control panel

5 tips to designing an electrical control panel

The fundamentals of control panel building and design are straightforward. Cost is always a consideration, but so is a tidy design, easy operator controls, and dependable functioning. Simple panel designs are less expensive to manufacture and run, as well as easier to maintain.

It helps to realise that design is a process. After you start something, you often think you know exactly what you want, only to discover that you want something quite different when you’re through.

When you first write out your design requirements, they appear disorganised. That’s quite typical. Nobody gets things perfect the first time. Design is an iterative process that takes time to perfect.

Rewrite your specifications till they’re well-organized and understandable. Understand what you want, put it out in plain English, and then go on to the hardware design.

1 . Start Physical

2 • Analyse the power circuits

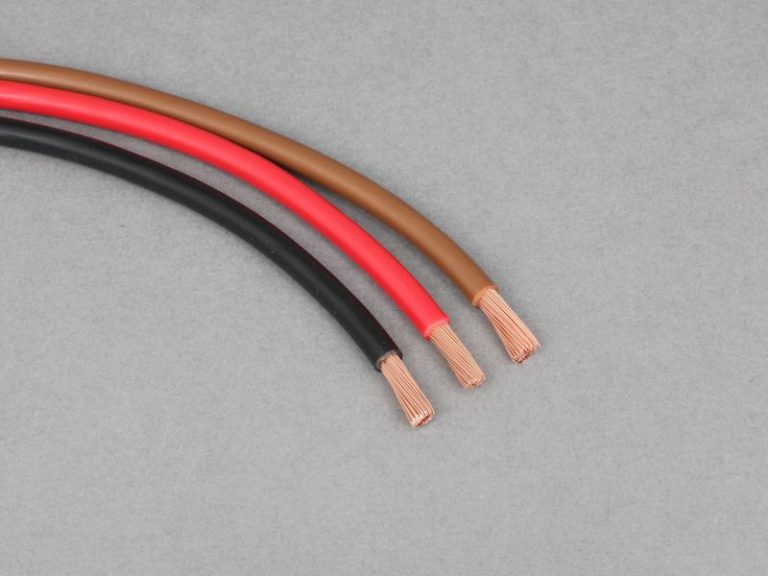

Determine the needed wire size and circuit protection for each power circuit.

The circuit will be able to deliver the appropriate load current if the wire size is correct.

The proper circuit protection prevents the wiring from overheating and catching fire.

Determine the size of the power cable based on the load current.

Power circuit protection should be chosen based on wire size.

Then, based on voltage and load current, decide the optimal power component type to utilise and the appropriate size.

The proper size ensures that it will perform as expected, and the right size ensures that it will safely carry the load.

3 • use the best control type

Always begin with the most basic control components (Relays, Timers, etc.) When a basic solution isn’t enough, use a programmable Smart Relay or a Programmable Logic Controller (PLC). These offer substantially more functionality, but they also necessitate the use of a computer and programming software, as well as the knowledge of how to create the desired functionality.

A Programmable Logic Controller is used by certain control panel designers as a starting point . Although a PLC may be the best option in some cases, you should always select the simplest control type that is suited for the application.

4 • use the best operator device

Always begin with the most basic operator devices (Pushbuttons, Pilot Lights, Digital Panel Meters, etc.). Add a Color Graphic door laminate for a sophisticated look. Use a colour touch screen display as the Human Machine Interface when needed. This adds a lot of functionality, but it also necessitates the use of a computer, programming software, and someone who knows how to develop the needed capability.

A Human Machine Interface (HMI) is a starting point for certain control panel designers. Although an HMI may be acceptable in some cases, the simplest operator device type appropriate for the application should always be used.

5 • use the best in class products by category

By product category, experienced control panel designers employ the best-in-class components. This is a personal opinion based on product knowledge. Control panel designers with experience are aware of the wide range of goods offered in each product category. This enables individuals to compare and use products that offer the best value for money in terms of price, form, and function.

Some control panel designers attempt to use a single manufacturer for all of the panel’s components. This is something that many European companies do, and some American ones do as well. There are situations when this makes sense, but in most cases, it restricts your ability to employ best-in-class items by product category.

What we can offer

We offer a wide range of control panel building, from compact enclosures, to large standing enclosures, featuring bespoke designs or built from customer diagrams. These panels we offer can be large batches or just one off’s this depends on your needs.

Who is the service for?

These services can be offered to any customer, depending on their interests. We can provide a large variety of panels. These panels are produced to meet your requirements.

Brands we use

The PLC’s that we use vary from companies such as, Siemens, Omron, Mitsubishi and Allen Bradley, depending on the complexity of control required. Other products incorporated are from various companies such as Murr, Pilz etc.. These companies provide the likes of safety relays and power supplies.

Additional Information

For any additional information on our panel building capabilities, or for any inquiries, don’t hesitate to contact us.

Panel Building

See some of our work

click on an image for further details.